A new material used in pharmaceuticals, automobiles, aviation, and semiconductors! From battery conductive materials to sports equipment like hockey sticks and golf clubs, shielding plastic for electronics, and improving the durability and strength of automotive components, CNT (Carbon Nano Tube) comes useful in all industries! Today’s FOCUS ON will look thoroughly into the next-generation material, CNT.

CNT, a material of our dream,

surpassing the features of existing materials

CNT, short for Carbon Nanotube, was first discovered in 1991 in Japan by Dr. Sumio Ijima of NEC Research Lab. Its diameter is a nm (nanometer) scale, but it has been dubbed ‘the new material of our dream’ for its high electric conductivity and heat conductivity.

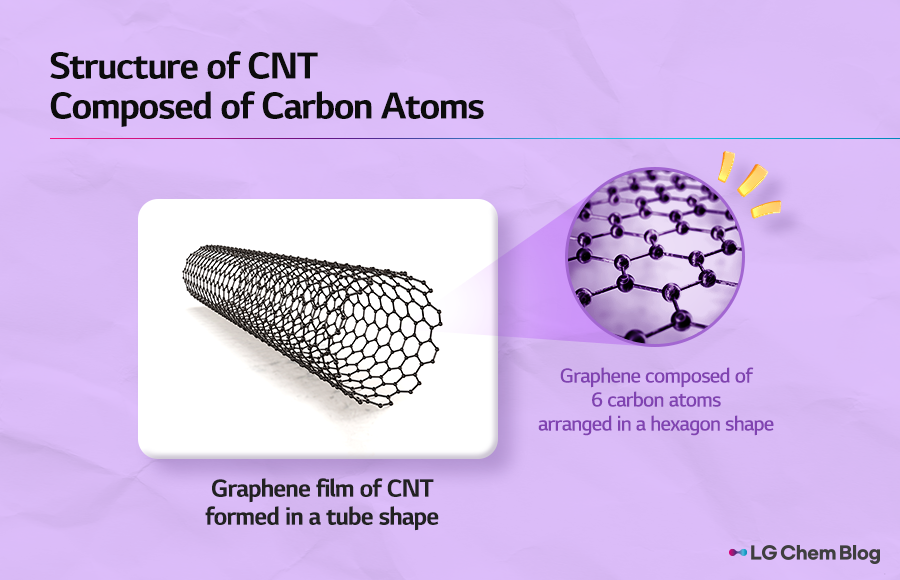

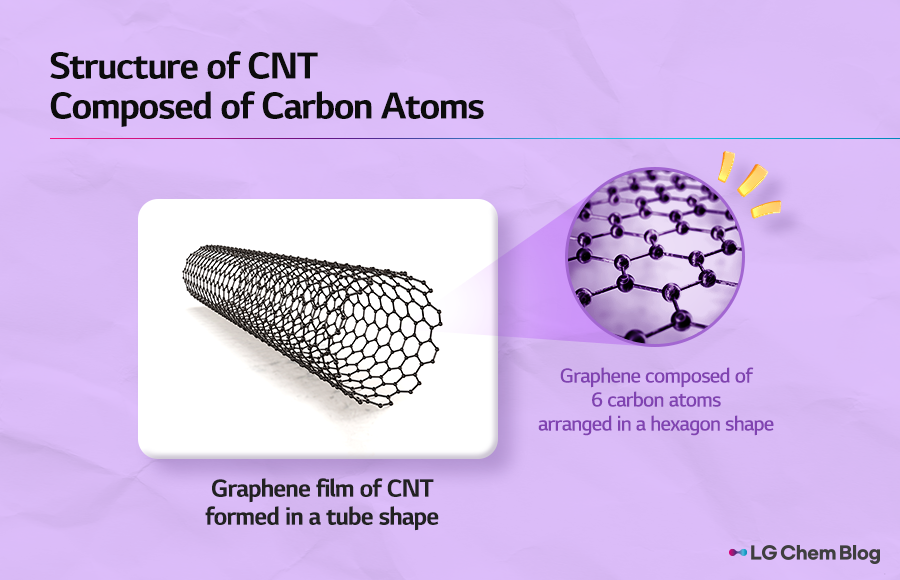

CNT is an allotrope* of carbon, possessing a cylinder-shaped nano structure. It gained its name from the tube-shaped Graphene film that consists of carbon atoms. Depending on at what angle the Graphene film is rolled into a tube shape, nanotubes come with different shapes and diameters, which determine their use in metals or semiconductors.

*Allotrope: a substance whose molecules or crystals are made of atoms of the same element, but with different arrangement of the atoms

CNT’s strength is 100 times that of steel, which makes it the strongest material that has ever been discovered. Also, its electric conductivity is equivalent to that of copper, and heat conductivity similar to diamond. Its lightness and flexibility, owing to the tube shape and hollow space inside, make it stand out even more. As the material is composed entirely of carbon, it is stable in chemical reactions and easy to synthesize with other materials. Yet, its thickness is only a nanometer scale, which is 1/10,000 of a piece of hair. Thus, we can secure excellent electric conductivity at minimal input.

Applications of CNT

CNT is known as an essential material of EV batteries. Not only that, it is also used in automotive exterior (side mirrors, car seats, heated handles), aviation, secondary batteries, semiconductors, etc. With excellent electric conductivity and elasticity, it makes a great material for the exterior and wheels of automobiles, airplanes, and space crafts. Moreover, CNT is found in electronic devices, particularly in conductive substrates and semiconductor circuits, and various other fields including semiconductor, flat display, super-strong fiber, biosensors, and so on.

CNT is also applied to secondary batteries, both in cathode and anode. When CNT is used as a conductive additive* in the cathode, it embodies higher conductivity than the conventional conductive additive made of carbon-black. This means we can use less conductive materials and fill the space with anode, maximizing the battery capacity and lifespan. High conductivity contributes to battery charging speed, increased safety, and battery lifespan. LG Chem supplies CNT for conductive additives to battery players such as LG Energy Solution. There, CNT is used to maximize battery capacity and lifespan by helping the electric and electronic flows.

CNT is also used in the anode, which contains silicon active materials. CNT enhances the cell lifespan by maintaining the strong conductive network amid the expansion and contraction of the silicon active materials. While silicon anode gains attention as a next-generation anode material, the role of CNT is becoming more important.

*Conductive additive: a substance which stimulates the transfer of electrons between electrode active materials

LG Chem’s CNT business reaching out to the world

LG Chem has developed high-conduction and high-disperse CNT which heightens the material’s performance, and is now expanding their business to the global markets, including Japan, China, America, and Europe. While maintaining their research to make CNT’s conductivity more efficient, the company obtained over 550 CNT patents. Currently in operation are 3 CNT plants in Yeosu, Korea, and have commenced construction of the 4th CNT factory in Daesan.

LG Chem’s 4th CNT plant is expected to have annual 3,200 tons of production capacity. With the completion of the CNT4 plant, the company will secure annual 6,100 tons of CNT, which is more than twice of the current production capacity. Needless to say, it is the largest CNT plant in Korea, which will prepare the company for a high-speed growth of the global CNT market.

Today, we focused on the next-generation material, CNT. With active development of EV and its rising demand, the demand for battery materials is also increasing. In line with the trend, R&D of CNT for EV batteries is also in full swing. Please keep your support for CNT, which will continue to improve.

There are no comments yet! Be the first to let us know your thoughts!