Since LG Chem’s declaration of 2050 carbon-neutral goal, the word ‘eco-friendly’ has been gaining more weight. Companies are putting all-time-high efforts to reduce their carbon footprints and build sustainable life for humanity. Also keeping pace with the trend, LG Chem launched their first eco-friendly materials brand, LETZero.

The brand name LETZero is the combination of ‘Let’ and ‘Zero(0),’ signifying the company’s motto of ‘zero harm to nature, zero net-increase of carbon emissions.’ With the kick-off of LETZero, LG Chem began their journey towards zero(0) with hope for a better future of humanity. Under the LETZero lineup are Recycled products based on waste plastics, Bio-Circular Balanced products based on renewable plant raw materials, and Compostable products derived from corn-based glucose and waste-glycerol. Meet LETZero Encyclopedia, as LG Chem introduces LETZero and their proudly-invented eco-friendly materials.

Check out the first page of LETZero Encyclopedia, about LG Chem’s PCR ABS material made of waste plastics, how it is recycled and applied to diverse eco-friendly products!

Recycled Plastic Material! PCR ABS

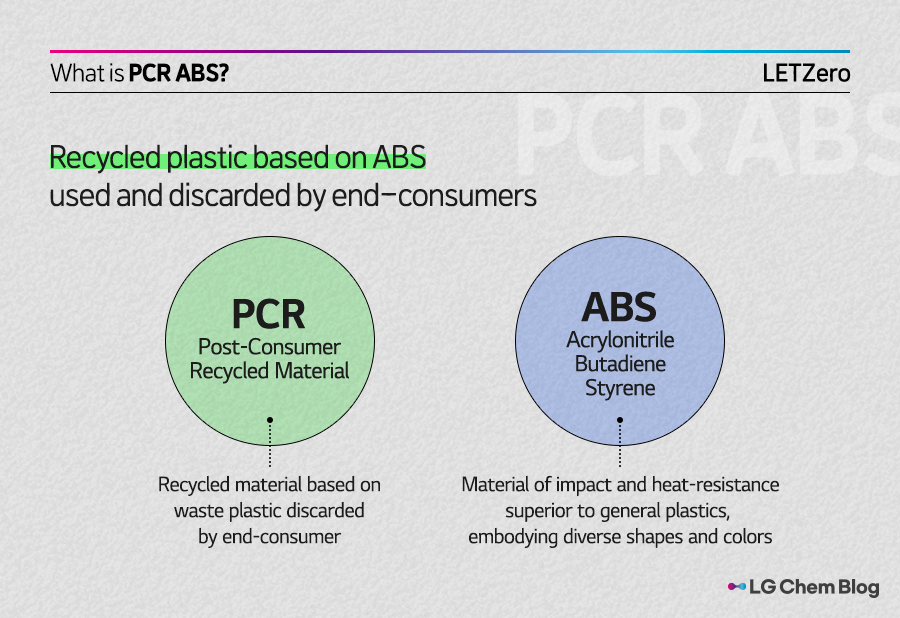

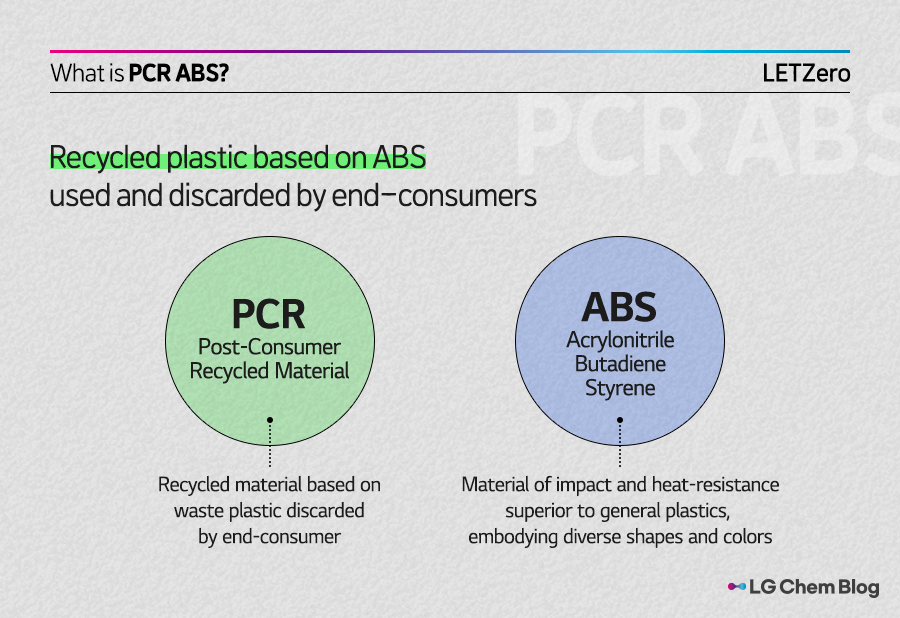

Recycled plastic is not a new concept. Yet, you might not be familiar with how it is processed. The term ‘PCR’ is short for ‘Post-Consumer Recycled material,’ which refers to the material made by recycling waste plastics used and discarded by end-consumers. ‘ABS’ is an abbreviation for the copolymer of Acrylonitrile, Butadiene, and Styrene. It is well-known for the impact and heat resistance superior to general plastics, and the ability to implement diverse shapes and colors that suit a wide range of products. In summary, PCR ABS is a recycled material based on ABS plastic used and discarded by end-consumers.

The production process of PCR ABS

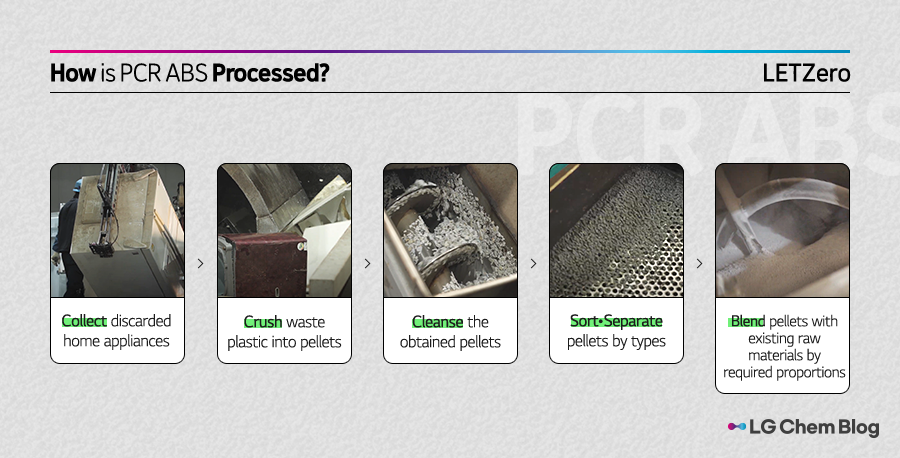

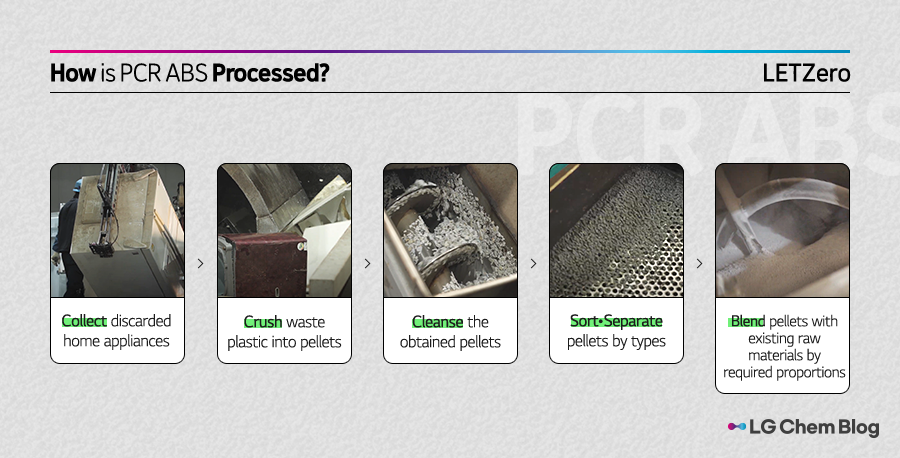

PCR ABS is processed by the mechanical-recycling method. Although it does not involve changing the chemical structure of collected waste plastics, careful sorting and processing allows the output to offer quality equivalent to brand-new plastic materials.

The process begins with collection, in which waste plastics such as TV, computers, and refrigerators used and discarded by end consumers are gathered at the recycle centers. Then follows crushing and turning the plastics into pellets, an early form of raw material. Next, the pellets are carefully cleansed and sorted through various sorting•separation processes, including water immersion separation based on the weight difference, separation using infrared spectroscopy, separation by static electricity, etc. The final stage is blending the pellets with traditional ABS raw materials to be applicable for future productions.

ABS, by nature, can embody diverse colors. Therefore, countless colors are blended in the recycling process of ABS, leaving mostly black or gray-colored pellets for the PCR ABS. This has been somewhat limiting the use of PCR ABS in products with high whiteness.

Yet, with LG Chem’s success of developing world’s first white-colored PCR ABS, the material procured a wider range of application. White-colored PCR ABS requires sorting and selecting of waste plastics with bright colors before they get crushed into pellets. The LG Chem research team carried out long-term experiment and analysis on the selection and formulation of white pigments, eventually discovering the optimal conditions for the better expression of white color. White-colored PCR ABS offers same quality as the original material, and can be modified into different shapes, designs, and colors to suit the ideal product.

The application of PCR ABS

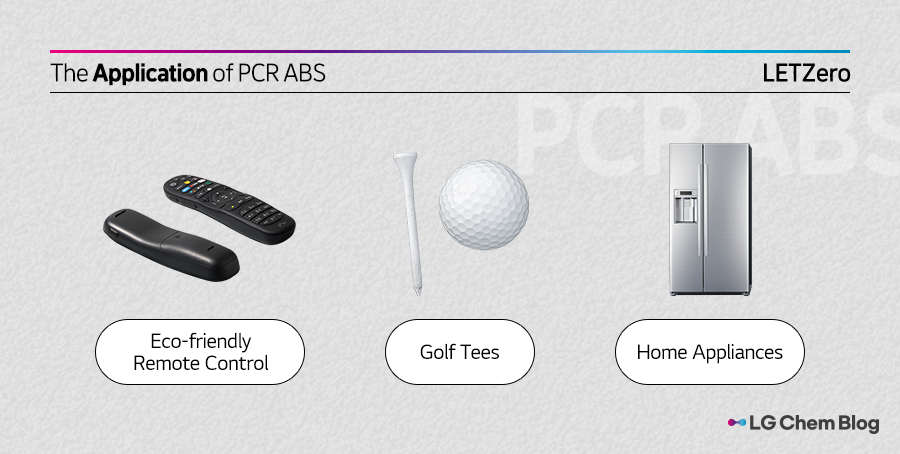

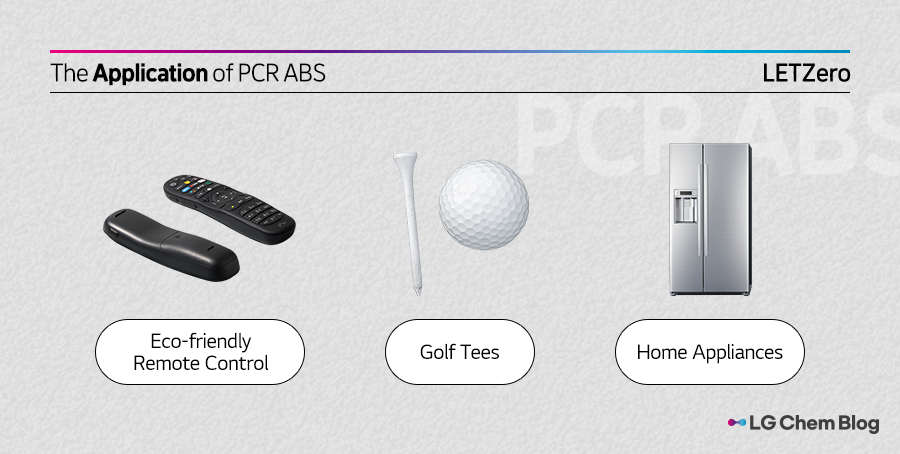

PCR ABS is applied to various products, including automotive parts, home appliances, and cosmetic containers. It is also found in remote controls used to switch channels, golf tees to prop the golf balls, automotive interior/exterior parts, TVs, and refrigerators. In October 2022, LG Chem partnered with LG U+ to develop a remote control based on PCR ABS. Given that companies replace the remote control productions with PCR ABS, it is expected that annual 11 tons of plastics and 3.3 tons of carbon emissions can be reduced. This is equivalent to the effect of planting 500 pine trees.

So far was an introduction to LG Chem’s eco-friendly material, PCR ABS. Look forward to the next LETZero Encyclopedia on Bio-Circular Balanced NPG!

There are no comments yet! Be the first to let us know your thoughts!