In early 2022, LG Chem unveiled a plan to expand their battery materials business more than 12 times between 2021 and 2030 by increasing revenues from $1.3 billion (KRW 1.7 trillion) to $16.2 billion (KRW 21 trillion). Aspiring to become the world’s leading battery materials company, LG Chem decided to build the fourth CNT (Carbon Nanotube) plant. The purpose is to gain a competitive edge in the rapidly growing global CNT market driven by cathode materials and electric vehicle (EV) batteries. LG Chem’s CNT will be used as a cathode conductive additive by LG Energy Solution and other battery companies. LG Chem also has a plan to increase the supply of CNTs in various industries. Find out more about LG Chem’s plan to build the fourth CNT plant in terms of changes in output and future business plans.

CNT, a next-generation material and a core component of EV batteries!

CNT is a next-generation material that has the same electric and thermal conductivity as copper and diamond, and is 100 times stronger than steel. CNTs have broad applications including EV batteries, conductive paint, anti-corrosive, antistatic exterior auto parts, and a planar heating element that prevents black ice on the road. When used in cathode conductive additive for a battery, CNT boasts over 10% higher conductivity than existing carbon black material, and thus, reduces the use of conductive additive by nearly 30%. In its place, more cathode materials can be filled to increase battery capacity and life. CNTs are also deemed as a main conductive additive for next-generation batteries sector including anode and all-solid-state lithium-sulfur batteries. LG Chem supplies CNTs to battery firms, which in turn, process them into cathode conductive additives to manufacture batteries.

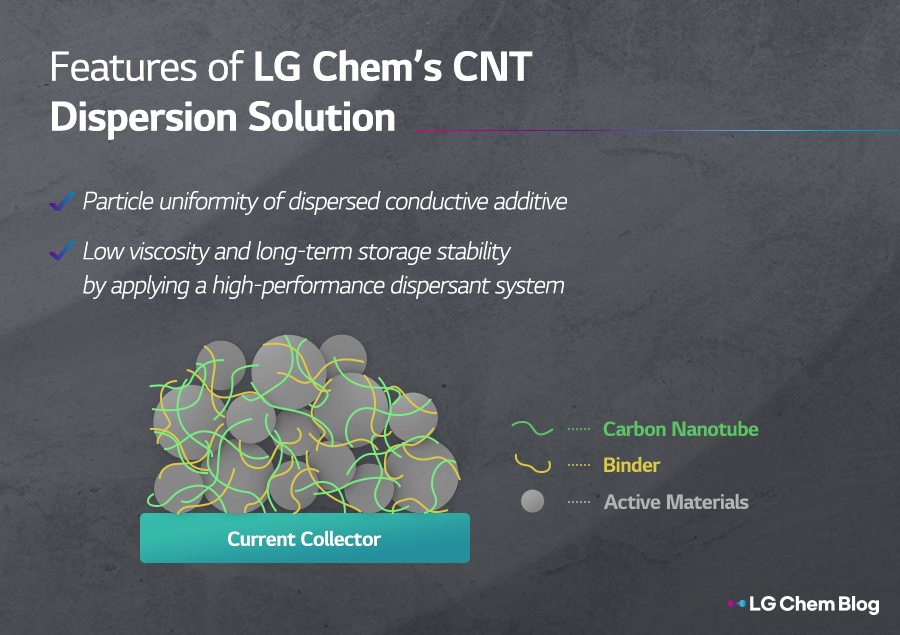

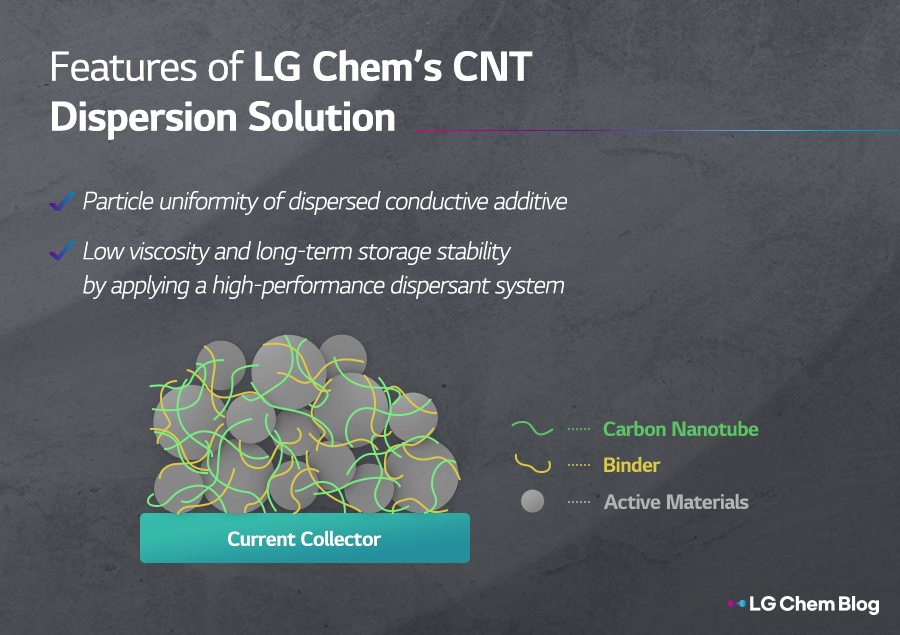

LG Chem’s unique CNT dispersion solution

CNTs have excellent conductivity, and it is important to disperse CNTs evenly to improve battery performance. With a cylindrical shape, CNTs are harder to distribute evenly than carbon black, and thus they perform better in a liquid form of dispersion. LG Chem’s CNT dispersion can evenly disperse CNTs in a solvent. LG Chem’s excellent quality of dispersion and processing technologies make it possible to prevent gelation of CNTs and enhance storage stability. Using CNT dispersion as a conductive additive improves battery performance.

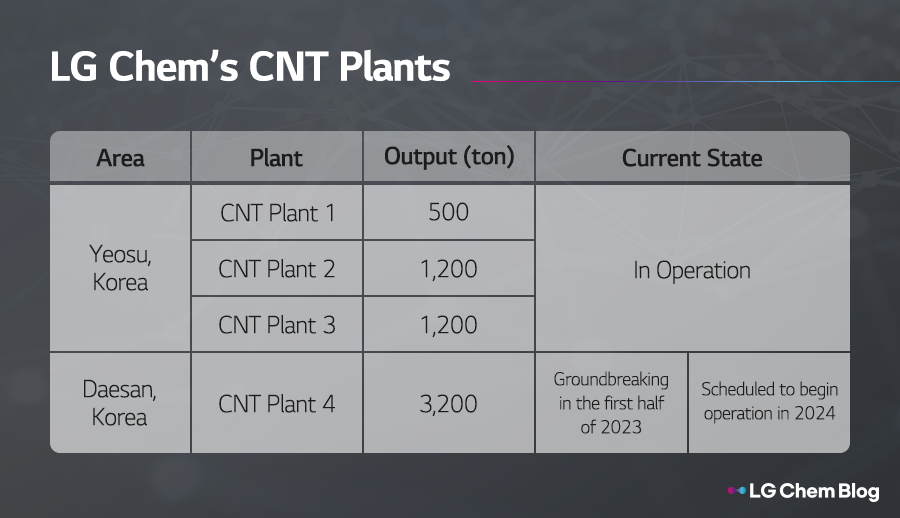

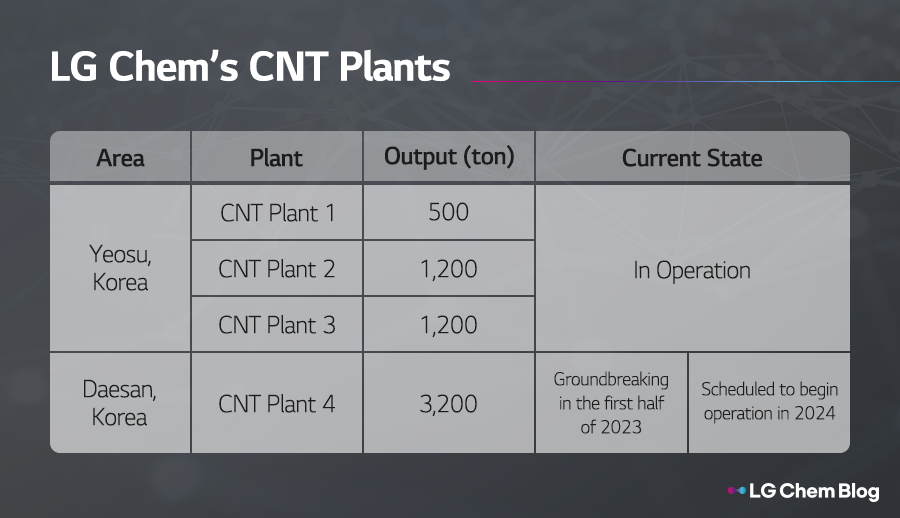

LG Chem manufactures 6,100 tons of top-quality CNTs each year!

The newly built fourth CNT plant will produce 3,200 tons of CNT annually. Once completed, LG Chem’s gross production capacity for CNT will be 6,100 tons each year, including 1,700 tons from the first and second plants and 1,200 tons from the third plant. Improvement in reactor stability and automation of manufacturing process have improved the production efficiency, and the productivity per worker has increased by 20%. Construction of the fourth CNT plant will begin in the first half of 2023, and the new plant will begin operation in the second half of 2024.

At LG Chem’s CNT plant, thanks to the independently developed fluidized bed reactor (FBR), CNTs up to 600 tons per production line can be produced annually, the largest capacity in the world. At CNT plants, Fe is broadly used as a catalyst, but it requires a separate post-treatment process as it contains a relatively higher amount of metal and magnetic sludge compared to cobalt (Co). To address this problem, LG Chem developed a Co-based catalyst to reduce the content of magnetic sludge that affects battery quality, and could manufacture top-quality CNTs.

Rapidly growing LG Chem’s CNT business moves forward!

The CNT market for conductive additive of batteries is expected to grow to $2.3 billion (KRW 3 trillion) by 2030. Between 2021 and 2030, the global CNT demand is expected to increase by over 30% each year from 5,000 tons to 70,000 tons. Currently, LG Chem is increasing CNT revenues from new clients other than LG Energy Solution. Based on top-quality CNT, LG Chem endeavors to earn the trust of carmakers. The company also has a vision to increase CNT sales in new areas including antistatic paint, planar thermal element that prevents black ice on the road, and trays used in semiconductor manufacturing. Applying CNTs to trays used in semiconductor manufacturing increases the heat resistance property of semiconductors and helps to block dust, electromagnetic waves, and static. CNT is a versatile material and has a strong growth potential.

Based on manufacturing competitiveness and excellent quality, LG Chem strives to be the leading manufacturer of conductive additives for batteries, and make forays into the global market. LG Chem will also increase the supply of CNTs in more diverse industrial areas.

There are no comments yet! Be the first to let us know your thoughts!